-

5/F, Building 12, Xinxintian Industrial Zone, Xinsha Road, Shajing Street, Shajing 2 Community, Bao'an District, SZ, China.

PCB Assembly Manufacturing Plant

We Started in 2012

Since 2012, our PCB Assembly Manufacturing Plant has been a trusted partner for businesses seeking top-tier electronic manufacturing services. We specialize in providing comprehensive PCB assembly solutions, from prototype to high-volume production. Our commitment to quality and efficiency, coupled with continuous investment in advanced equipment and skilled personnel, ensures exceptional results for every project.

01.

OUR ADVANTAGE

1.Quality assurance;2.On-time Deliver;3.Competitive Price;4.24 Hours Customer Service;

02.

OUR CERTIFICATION

ISO9001,ISO14001 ISO13485 IATF16949 RoHS,UL/CUL, CE

03.

OUR TEAM

120+ QA 100+ Engineers 1200+ Professional Employees 13+ Years PCB&PCBA Experience

Why Choose With Us

One-Stop Solution: From PCB design and fabrication to assembly and testing, we offer a complete solution under one roof. We have an instant online system to make getting a quotation as easy as possible.

Experienced Assembler: Our team of experienced engineers and technicians is dedicated to delivering high-quality PCB assembly services.

Advanced Equipment: We invest in state-of-the-art equipment to ensure precision, efficiency, and reliability.

Quick Turnaround Time: We offer competitive turnaround time for both prototype and production orders.

Customer Focus: We are committed to providing excellent customer service and support.

13 years of manufacturing experience

12,000 square meters of modern plant

1200 employees with 28 automated machines

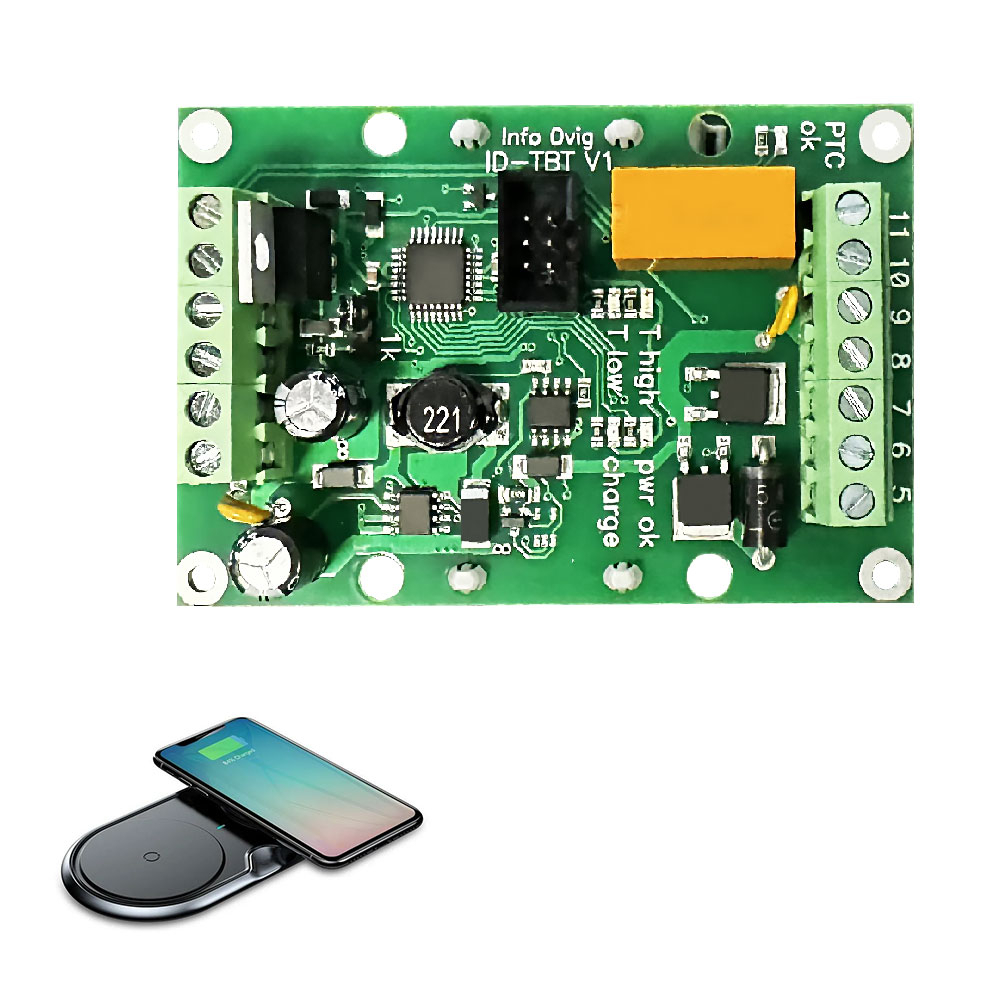

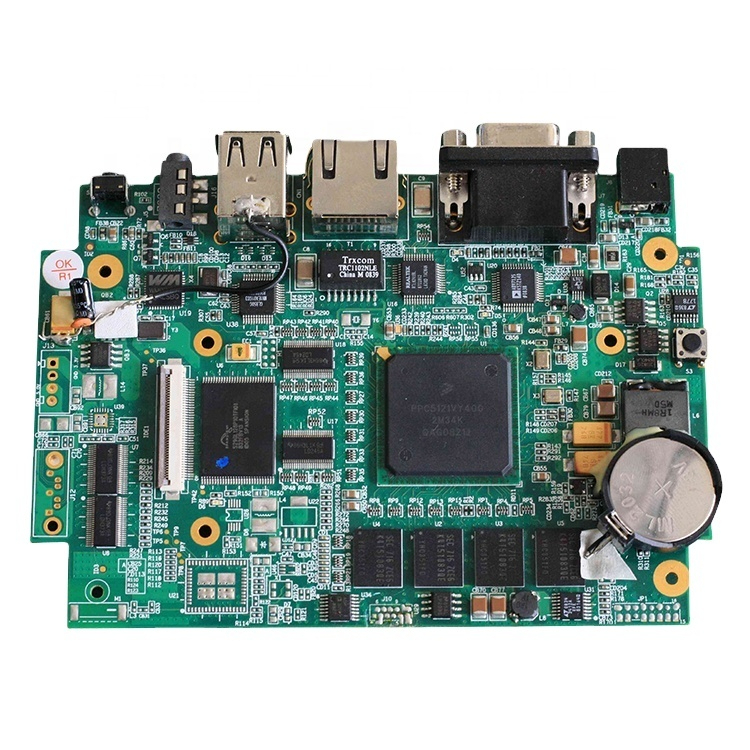

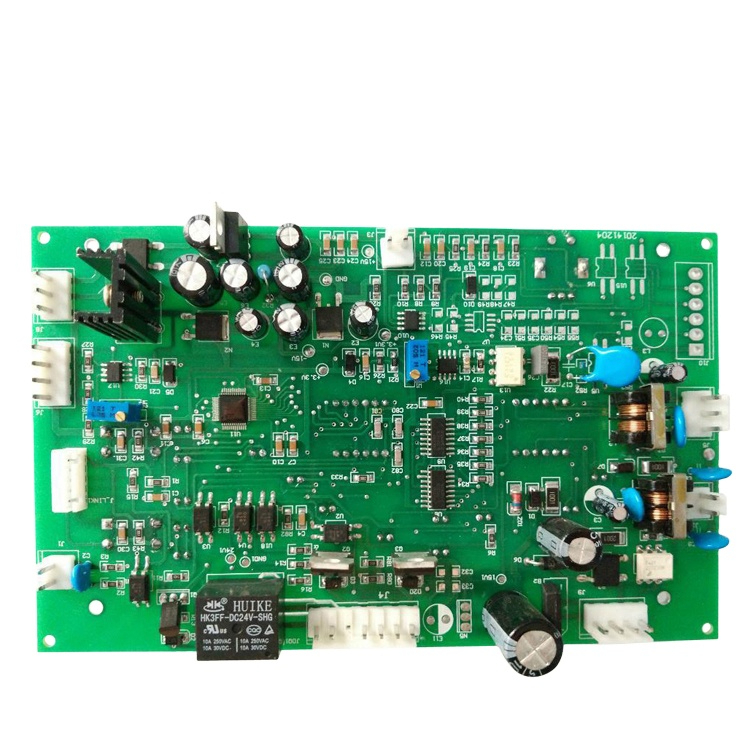

Products We Are Proud Of

These products reflect our strict standards for quality and user experience. Each product is carefully designed to meet the needs and expectations of our customers.

Certificates Obtained

Through rigorous audits and evaluations, our products and services meet international and industry standards to ensure that our customers receive the highest quality experience.

What Our Client’s Say

As a product design firm, we often need quick turn PCB prototypes to validate our designs. Hua Yuan Heng has consistently delivered high-quality PCB assembly services with impressive speed. Their assembly process is efficient, and the solder joints on the assembled board are always clean and reliable. Their SMT assembly capabilities are top-notch, and they can easily handle complex circuit designs with a large number of SMDs on a single plate. Their pick-and-place machine is very accurate when placing the parts onto the soldering paste. I would highly recommend their prototype PCB assembly process. I'm confident they can handle volume PCB assembly as well. They are a great PCB manufacturer. We've also used them for PCB fabrication, and the quality of the printed circuit board has been excellent. Their assembly lead time is also amazing. Highly recommend for anyone needing a prototype or even batch production.

We've been working with Hua Yuan Heng for our PCB assembly needs for over a year now, and we are extremely satisfied with their services. They've handled several PCBA orders for us, ranging from simple to complex mixed assembly designs involving both surface mount and through-hole components. Their AOI and X-ray inspection processes ensure the quality of each circuit and give us confidence in the reliability of the final product. The solder mask is always applied perfectly, and the silkscreen is clear and easy to read. Even on more complex PCBs, the solder joints are always perfect after the reflow process. Their assembly capabilities have exceeded our expectations, and their turnaround time has been outstanding."

"Hua Yuan Heng is a reliable partner for board fabrication and assembly. Their team is knowledgeable and responsive. They carefully reviewed our Gerber data and BOM and provided valuable DFA feedback to improve our PCB design and minimize the risk of issues during the assembly process. It's clear that they take every precaution to prevent PCB fails. Their manufacturing process is impressive. They use AOI to make sure each circuit is correct and every component is placed in the correct location. After being placed by the pick-and-place machine, the plate is sent through the reflow oven where each circuit is bonded to the board. After this, the assembled board is sent for a functional test where power and simulated signals are applied to test the circuit. They are a great board manufacturer and assembler. I highly recommend their PCB assembly services."

We recently switched to Hua Yuan Heng for our PCB assembly needs, and we've been very impressed. Their PCB assembly process is well-defined, and they pay close attention to detail. They handle both SMT and THT (through-hole) assembly with expertise. I was very impressed with the wave soldering that they did on our through-hole components. The wave of molten solder made the perfect connection on the bottom of the board. The solder connections on all our assembled boards are consistently strong, and we've had zero defects. They can easily handle all types of electronic components, even ones that require manual soldering. We gave them one design with a very large capacitor that needed to be placed by hand, and it was no problem for them. Their customer service is also excellent. Any time we need a quotation, we can get one with their instant online system. If that doesn't work, we just contact us, and someone always gets back to us quickly. Please contact us if you have any questions about this amazing assembler

上一项

下一步

Frequently Asked Questions

By organizing and answering the most common questions from our users, we hope to help you better understand our products and services and address your concerns during use.

Absolutely! We specialize in mixed assembly, handling both surface mount and through-hole technologies. We can work with any electronic components that you need for your circuit. For through-hole, we offer both manual soldering and wave soldering, depending on your project’s specific requirements. For prototype orders, we offer quick turn services to get your assembled board to you as quickly as possible. If you send us your Gerber data and BOM, we can give you a more accurate lead time and quotation. Our assembly team is highly experienced with complex PCB designs, and we are confident that you will be happy with the results. We are the best PCB manufacturer in Shenzhen.

Quality is our top priority. We utilize advanced inspection methods, including AOI (Automated Optical Inspection) and X-ray inspection. Our AOI machine uses high-powered cameras to examine the boards from different angles to view each circuit and verify component placement and solder joint integrity, identifying potential problems before the final inspection. X-ray is used for inspecting solder connections under components like BGAs. After assembly, every board undergoes a rigorous functional test using power and simulated signals. We can also provide detailed reports on the number of scrapped boards during production. We want to be your board manufacturer for life, so please contact us with any other questions

As a full-service PCB manufacturer, we offer in-house PCB fabrication and have experience with a wide range of materials and finishes. We can help you choose the best options for your specific application. We routinely apply solder mask to protect circuit traces and can customize the silkscreen with your part numbers, logos, and other markings. We understand the importance of these details for product identification and branding. You can rest assured that your PCBs will meet the highest standards. We even offer help with PCB design

Our SMT assembly process begins with applying soldering paste to the prepared PCB pads using a precision stencil. We then use advanced pick-and-place machine to accurately place surface mount components (SMDs), including fine-pitch integrated circuits, onto the board. The boards are then passed through a carefully controlled reflow oven in a reflow process to create strong and reliable solder connections. Our equipment is regularly calibrated and maintained to ensure optimal performance. We use a special robotic device to place a small amount of solder onto each plate before the components are placed. This helps ensure that the mount components are soldered securely. The soldering process is the most important part of the assembly, and we take every precaution to make sure that it is done perfectly

We understand that time is often of the essence. Our standard turnaround time for PCB assembly is competitive, and we also offer expedited services for urgent projects. We can often accommodate quick turn requests, depending on the complexity of the assembly and our current production schedule. We’ve invested in a new system that allows you to get an instant online quotation. If you have a specific deadline in mind, please contact us, and we’ll do our best to meet your needs. We want to be your assembler for all of your PCB needs. Whether you’re looking for PCB fabrication or assembly, we are the right partner for you

Yes, we have extensive experience with mixed assembly and regularly handle projects involving both SMT and PTH components. Our technicians are skilled in both manual soldering and wave soldering techniques. Our wave soldering machine is specifically designed to create a precise wave of molten solder, ensuring reliable connections for through-hole components on the bottom of the board. The soldering method used will depend on the components and the overall PCB design. The hole in the PCB is designed to perfectly fit the leads of each component. We can also offer design considerations for your circuit. We can provide DFA (Design for Assembly) support to optimize your PCB design for manufacturability, ensuring a smooth assembly process and reducing the risk of PCB fails. We keep a large inventory of electronic components, so we will likely have the components need for your assembly. After the assembly, we use an AOI machine to inspect the PCBs. We also do a functional test to make sure everything works. We are experts at printed circuit board assembly

Latest from Blog

Our blog content will provide you with a wealth of information and inspiration. They not only reflect our expertise and experience, but also encourage you to explore and discuss relevant topics with us.

how to clean printed circuit boards

The Ultimate Guide to Cleaning a Circuit Board: Removing Corrosion and Ensuring Optimal Performance This article provides a comprehensive…

How to assembe own pcb solder mask

Mastering the Art of PCB prototypes are vital for testing designs before full production. Solder Mask: Your Ultimate Guide…

上一项

下一步