-

5/F, Building 12, Xinxintian Industrial Zone, Xinsha Road, Shajing Street, Shajing 2 Community, Bao'an District, SZ, China.

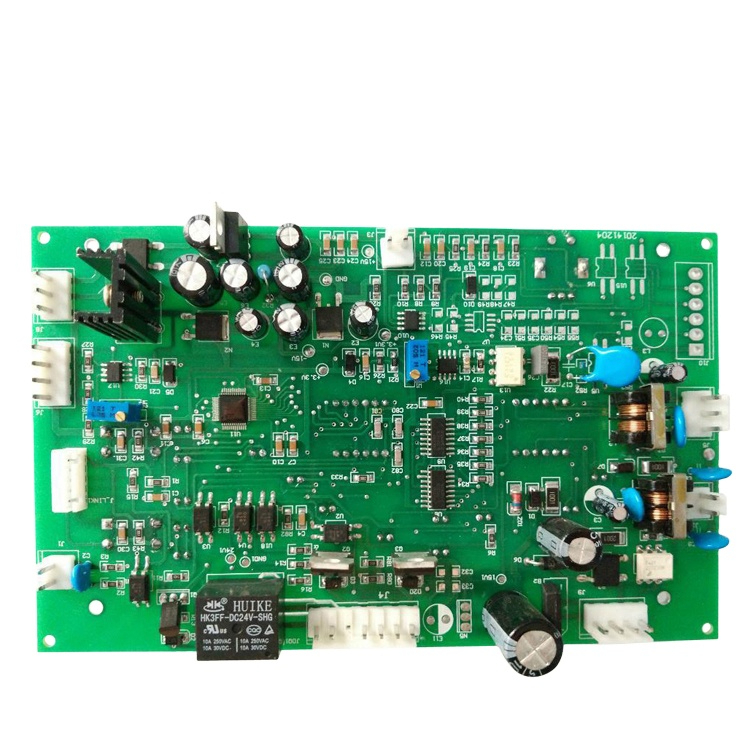

how to clean printed circuit boards

The Ultimate Guide to Cleaning a Circuit Board: Removing Corrosion and Ensuring Optimal Performance

This article provides a comprehensive guide on how to effectively clean a circuit board, with a special focus on removing corrosion. As experts in print circuit board and print circuit board assembly manufacturing, we understand the critical importance of maintaining clean circuit boards for the optimal performance and longevity of electronic devices. Whether you are a PCB design company or an electrical manufacturing firm, this guide will offer invaluable insights into preserving the integrity of your PCBs. We will delve into various cleaning techniques, the importance of regular maintenance, and how to address issues like corrosion effectively. By the end of this article, you will have a thorough understanding of how to clean circuit boards and why it is a crucial aspect of electronic device maintenance.

Article Outline

Table of Contents

- Why Do Circuit Boards Get Dirty and Why is Cleaning Them Important?

- Identifying Different Types of Contaminants on Circuit Boards

- How to Choose the Right Cleaning Agent for Your PCB?

- What are the Essential Tools for Cleaning Circuit Boards?

- Step-by-Step Guide: How to Clean a Circuit Board Effectively?

- Advanced Techniques: Ultrasonic Cleaning for Delicate Circuit Boards

- How to Prevent Corrosion on Printed Circuit Boards?

- What to Do When You Encounter Severe Corrosion on a PCB?

- When Should You Consider Professional PCB Cleaning Services?

- Best Practices for Regular Cleaning and Maintenance of PCBs

Why Do Circuit Boards Get Dirty and Why is Cleaning Them Important?

Circuit boards get dirty due to various environmental factors and operational conditions. Dust, dirt, flux residues from soldering, and other contaminants can accumulate over time. In my experience working with print circuit board manufacturing, I’ve seen that even in controlled environments, circuit boards are susceptible to accumulating microscopic particles.

Cleaning circuit boards is essential for maintaining their performance and extending their lifespan. Contaminants can cause a range of issues, from overheating to short circuits, and even corrosion. For instance, flux residue, if not removed, can become conductive and lead to corrosion, affecting the solder joints and the overall functionality of the circuit board. Regular cleaning helps prevent these issues, ensuring that the electronic device functions correctly. As a PCB and PCB assembly manufacturer, we emphasize to our clients, especially PCB design companies, that proper maintenance, including cleaning, is as crucial as the initial design and manufacturing process.

Identifying Different Types of Contaminants on Circuit Boards

Circuit boards can accumulate various types of contaminants, each requiring a specific cleaning approach. Common contaminants include dust and debris, which can typically be removed with compressed air or a soft brush. Flux residue, a byproduct of the soldering process, often appears as a sticky or crusty substance around solder joints.

Another type of contaminant is corrosion, which can manifest as a greenish or whitish buildup on the circuit board. Corrosion is particularly concerning as it can degrade the conductive pathways and lead to component failure. Identifying the type of contaminant is the first step in effective circuit board cleaning. In our PCB manufacturing plant, we train our technicians to recognize these different contaminants to determine the most appropriate cleaning method.

How to Choose the Right Cleaning Agent for Your PCB?

Choosing the right cleaning agent for your PCB is crucial to ensure effective cleaning without causing damage. Isopropyl alcohol (IPA), particularly in concentrations of 90% or higher, is widely used due to its ability to dissolve flux and other organic contaminants without leaving residues. In addition to IPA, deionized water is used in many PCB cleaning processes, especially in ultrasonic baths. It’s important to avoid tap water due to its mineral content, which can leave residues or cause corrosion when the water is evaporated.

For more stubborn contaminants, specialized PCB cleaning solutions might be necessary. These solutions are formulated to tackle specific issues like heavy flux residues or oxidation. Here’s a table summarizing common cleaning agents and their uses:

| Cleaning Agent | Concentration | Use Case |

|---|---|---|

| Isopropyl Alcohol (IPA) | 90% or higher | General cleaning, flux removal, quick drying |

| Deionized Water | – | Used in ultrasonic baths, and cleaning organic and inorganic contaminants. |

| PCB Cleaning Solution | Varies | Heavy flux residues, oxidation, specialized cleaning |

| Acetone | – | Strong solvent, can damage some plastics, use with caution |

When selecting a cleaning agent, consider the type of contaminants present, the materials used in the PCB, and the sensitivity of the electronic components. In our experience, using the right cleaner not only ensures a clean circuit board but also extends the life of the electronic device.

What are the Essential Tools for Cleaning Circuit Boards?

Having the right tools is essential for effective circuit board cleaning. One of the most common tools is a lint-free cloth or swab for applying cleaner and wiping the circuit board surface. Compressed air is useful for removing loose dust and debris from hard-to-reach areas.

A soft-bristled brush, such as a paintbrush, can be used to gently scrub the circuit board. For more thorough cleaning, an ultrasonic cleaner can be employed. Ultrasonic cleaners use high-frequency sound waves to create cavitation bubbles in the cleaning solution, which effectively dislodge contaminants from the circuit board. In our PCB assembly process, we often use ultrasonic cleaning as it provides a deep clean without the need for harsh scrubbing.

Step-by-Step Guide: How to Clean a Circuit Board Effectively?

Cleaning a circuit board requires a systematic approach to ensure thoroughness and safety. Here’s a step-by-step guide:

- Preparation: Start by powering down and unplugging the electronic device. If possible, remove the circuit board from the device to facilitate cleaning. Ensure you are working in a well-ventilated area and wearing appropriate safety gear, such as gloves and eye protection.

- Initial Cleaning: Use compressed air to blow away loose dust and debris. This prevents these particles from being rubbed into the circuit board during subsequent cleaning steps.

- Applying Cleaning Agent: Moisten a lint-free cloth or cotton swab with your chosen cleaning agent, such as isopropyl alcohol or specialized electronic cleaner. Gently wipe the surface of the circuit board, paying special attention to areas with visible contaminants or corrosion. For hard-to-reach areas, use a soft brush dipped in the cleaning solution.

- Ultrasonic Cleaning (Optional): If you have an ultrasonic cleaner, place the circuit board in the device’s basket and submerge it in the cleaning solution. Run the ultrasonic cleaner for the recommended time, typically a few minutes.

- Rinsing: If you used a cleaning solution other than IPA, rinse the circuit board with distilled water to remove any remaining cleaner. This step is crucial to prevent residues from drying on the circuit board.

- Drying: Allow the board to dry completely. You can use compressed air to expedite the drying process or simply let it air dry. Ensure there is no moisture left on the circuit board before reassembling or powering on the device.

From my experience, following these steps meticulously leads to a clean and functional circuit board. It’s also essential to inspect the circuit board after cleaning to ensure all contaminants have been removed and there is no damage. If you are unsure about any step, remember that we offer professional cleaning services to help maintain your PCBs.

Advanced Techniques: Ultrasonic Cleaning for Delicate Circuit Boards

Ultrasonic cleaning is an advanced technique particularly useful for delicate circuit boards. It involves using an ultrasonic cleaner, a device that emits high-frequency sound waves to create millions of tiny bubbles in a cleaning solution. These bubbles implode upon contact with the circuit board surface, effectively dislodging and removing contaminants, even from the most intricate parts.

This method is highly effective for removing stubborn flux residues, microscopic dust and debris, and even some forms of mild corrosion. The key advantage of ultrasonic cleaning is its ability to clean thoroughly without the need for manual scrubbing, which can potentially damage sensitive electronic components. In our PCB manufacturing plant, we often employ ultrasonic cleaning for PCBs with complex geometries or delicate components. It ensures a deep clean while preserving the integrity of the circuit board. If you are dealing with high-value or sensitive PCBs, considering ultrasonic cleaning can be a game-changer.

How to Prevent Corrosion on Printed Circuit Boards?

Preventing corrosion on printed circuit boards is crucial for ensuring their longevity and reliability. Corrosion can degrade the conductive traces and solder joints, leading to malfunctions or even complete circuit board failure. One effective way to prevent corrosion is to apply a conformal coating to the PCB. This protective layer acts as a barrier against moisture, dust, and chemical contaminants.

Regular cleaning is another essential preventive measure. By removing contaminants like flux residues and dust, you reduce the risk of corrosion. Additionally, storing PCBs in a controlled environment with low humidity and stable temperature can significantly reduce the likelihood of corrosion. In our experience as a PCB manufacturer, we’ve found that a combination of conformal coating and regular maintenance is the most effective strategy for preventing corrosion and ensuring the durability of circuit boards. For those looking for top-tier protection, exploring multilayer PCBs could be an excellent next step in your project.

What to Do When You Encounter Severe Corrosion on a PCB?

Encountering severe corrosion on a PCB can be daunting, but it’s not always a lost cause. The first step is to assess the extent of the corrosion. If it’s limited to surface areas, you might be able to clean it using specialized corrosion removal solutions. These solutions are designed to dissolve corrosion without damaging the underlying circuit board material.

Apply the corrosion removal solution carefully using a lint-free cloth or swab. Gently rub the affected areas until the corrosion is removed. After cleaning, it’s crucial to thoroughly rinse the circuit board with distilled water and dry it completely. In cases of severe corrosion that has penetrated deeper layers of the PCB or affected critical components, it might be necessary to seek professional repair services. We often encounter such scenarios in our PCB assembly plant, and our experienced technicians can assess and repair severely corroded PCBs, restoring them to optimal condition.

When Should You Consider Professional PCB Cleaning Services?

While many circuit board cleaning tasks can be performed in-house, there are situations where professional PCB cleaning services are advisable. If you are dealing with high-value PCBs, complex designs, or sensitive electronic components, professional cleaning can ensure the best results without the risk of damage.

Professional cleaning services, like those we offer, have access to advanced equipment such as industrial-grade ultrasonic cleaners and specialized cleaning agents. Our technicians are trained to handle delicate circuit boards and can address issues like severe corrosion or stubborn contaminants. Additionally, if you need to clean a large volume of PCBs or require regular maintenance, outsourcing to a professional service can be more efficient and cost-effective. By leveraging our expertise, you can ensure that your circuit boards are maintained to the highest standards, prolonging their lifespan and optimizing their performance.

Best Practices for Regular Cleaning and Maintenance of PCBs

Regular cleaning and maintenance of PCBs are essential for their optimal performance and longevity. Establishing a routine cleaning schedule can prevent the buildup of contaminants and reduce the risk of corrosion. Here are some best practices to follow:

- Regular Inspections: Periodically inspect your circuit boards for signs of dust, flux residues, or corrosion. Early detection allows for timely cleaning and prevents minor issues from escalating.

- Use Proper Tools: Always use appropriate tools like lint-free cloths, soft brushes, and compressed air for cleaning. Avoid using abrasive materials or harsh chemicals that can damage the circuit board.

- Controlled Environment: Store and operate your PCBs in a clean, low-humidity environment to minimize exposure to contaminants and moisture.

- Conformal Coating: Consider applying a conformal coating to your PCBs to provide an extra layer of protection against environmental factors.

Incorporating these practices into your maintenance routine can significantly extend the life of your circuit boards. In our PCB manufacturing plant, we follow these guidelines rigorously to ensure the quality and reliability of our products. By adopting a proactive approach to cleaning and maintenance, you can safeguard your investment in electronic devices and ensure their continued performance.

FAQs

What is the best way to clean a circuit board?

The best way to clean a circuit board involves using isopropyl alcohol (90% or higher) and a lint-free cloth or soft brush. For a deeper clean, an ultrasonic cleaner can be used.

Can I use water to clean a PCB?

It’s best to use distilled water or deionized water to prevent mineral deposits. However, ensure the PCB is completely dry before using it again to avoid short circuits.

How often should I clean my circuit boards?

The frequency of cleaning depends on the operating environment. For devices in dusty or industrial settings, more frequent cleaning may be necessary. Regular inspections can help determine the appropriate cleaning schedule.

What should I do if I see corrosion on my circuit board?

For mild corrosion, you can use specialized cleaning solutions to remove it. If the corrosion is severe, it’s advisable to seek professional repair services to prevent further damage.

Is it safe to use compressed air to clean a circuit board?

Yes, compressed air is safe and effective for removing loose dust and debris from circuit boards. Ensure the air is dry and oil-free to avoid introducing new contaminants.

How do I prevent flux residues on my PCB?

Using a no-clean flux during soldering can minimize residues. If residues do occur, cleaning the PCB immediately after soldering with isopropyl alcohol can prevent buildup.

Conclusion

- Regular cleaning of circuit boards is essential for maintaining their performance and longevity.

- Different types of contaminants, such as dust, flux residues, and corrosion, require specific cleaning approaches.

- Isopropyl alcohol, distilled water, and specialized cleaning solutions are effective for cleaning PCBs.

- Tools like lint-free cloths, soft brushes, and ultrasonic cleaners play crucial roles in the cleaning process.

- Preventing corrosion involves applying conformal coatings, regular cleaning, and storing PCBs in a controlled environment.

- Severe corrosion may require professional intervention to restore the circuit board to optimal condition.

- Professional PCB cleaning services offer advanced equipment and expertise for handling delicate or high-value circuit boards.

- Establishing a routine maintenance schedule, including regular inspections and proper cleaning techniques, can significantly extend the life of your PCBs.

By following the guidelines and best practices outlined in this article, you can ensure that your circuit boards remain clean, functional, and reliable. Whether you are a PCB design company, an electrical manufacturing firm, or an individual hobbyist, maintaining your PCBs is crucial for the success of your electronic projects. If you have any questions or need assistance with PCB cleaning or maintenance, don’t hesitate to contact us. As a leading print circuit board and print circuit board assembly manufacturer, we are committed to providing top-quality products and services to meet your needs.