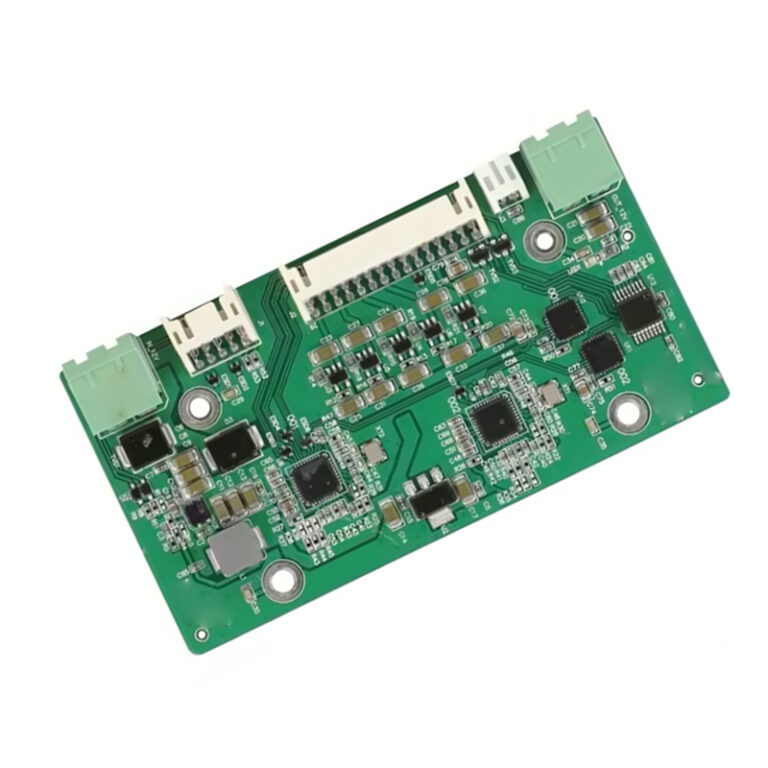

Professional custom pcb circuit boards manufactury

Mastering the Art of Printed Circuit Board Design and Manufacturing

In the dynamic realm of electronics, the printed circuit board (PCB) serves as the foundational element upon which innovation is built. As a premier printed circuit board and printed circuit board assembly (PCBA) manufacturing facility, we specialize in transforming intricate circuit designs into high-performance, reliable PCBs that power the world’s most advanced electronic products. Our commitment to excellence, combined with cutting-edge design software and advanced manufacturing processes, ensures that your PCB designs are realized with unparalleled precision and efficiency. By choosing us, PCB Design companies and Electronic product manufacturers partner with a leader who understands the complexities of modern PCB development and is dedicated to providing tailored solutions that exceed expectations. We don’t engage in retail-type sales; our focus is on empowering businesses with PCB solutions that drive technological advancements.

Unveiling the Intricacies of PCB Fabrication

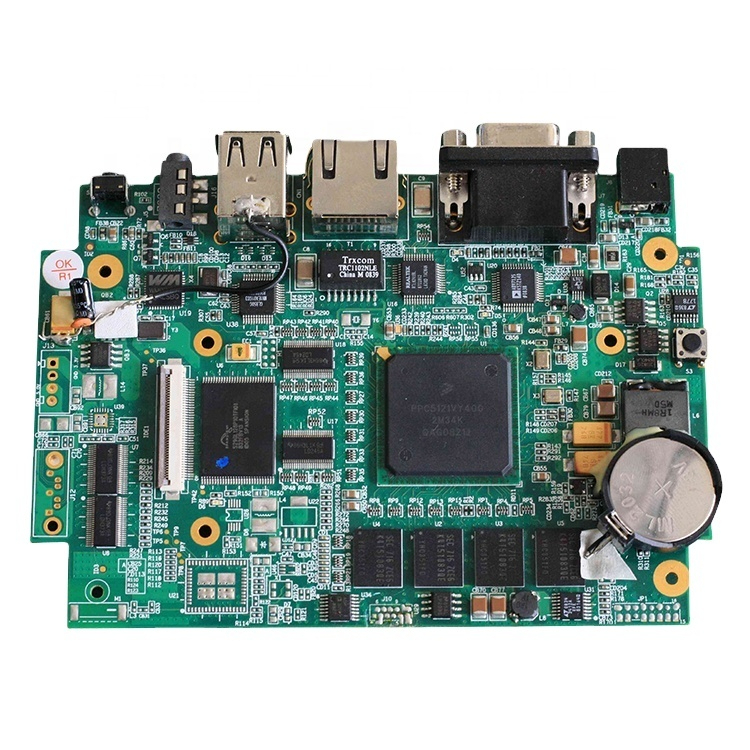

PCB fabrication is a complex, multi-stage process that demands meticulous attention to detail and a deep understanding of materials science and manufacturing technologies. We excel in transforming raw materials into high-quality PCBs that meet the specific requirements of your circuit designs.

Our fabrication process encompasses various techniques, including imaging, etching, drilling, plating, and applying the solder mask. We expertly handle a wide range of PCBs, from basic single-sided and double-sided designs to advanced multi-layer PCB and high-density interconnect (HDI) PCBs. We work with diverse substrate materials, including FR-4, polyimide, and metal-core options, allowing us to tailor the PCB to your specific application needs. The first step in pcb fabrication is imaging the circuit pattern onto the substrate. The unwanted copper is then removed through an etch process, leaving behind the copper traces that form the conductive pathways. Holes are drilled for vias and mounting through-hole components. The final step is the application of the solder mask, which protects the circuit and prevents solder bridges during assembly.

Optimizing PCB Layout for Peak Performance

PCB layout is a critical stage in the board design process that directly influences the functionality, reliability, and manufacturability of your electronic products. Our experienced team leverages advanced design tools to create optimized PCB layouts that adhere to industry best practices and stringent design rules.

| Stage | Description |

|---|---|

| Component Placement | Strategic placement of electronic components, including integrated circuit and passive components to minimize signal path length. |

| Trace Routing | Careful routing of traces to ensure signal integrity, minimize interference, and manage thermal considerations. |

| Power Distribution | Design of power and ground planes to provide stable power and minimize noise. |

| Thermal Management | Implementation of thermal vias and other techniques to dissipate heat effectively. |

During the pcb layout phase, careful consideration is given to component placement, trace routing, and power distribution. This ensures optimal signal integrity and minimizes electromagnetic interference. We utilize design software to ensure that all design rules are met and that the pcb is optimized for manufacturing. Our team has extensive experience in circuit board design for a variety of applications, including high-speed digital circuits and RF circuits. We work closely with our clients to ensure that the pcb layout meets their specific requirements. This phase involves transforming the schematic into a physical layout, determining the placement of electronic components and routing the copper traces. Using specialized pcb design software, our engineers meticulously arrange components to minimize signal path lengths, reduce electromagnetic interference, and optimize thermal performance.

Precision in Every Step of the PCB Assembly Process

Our comprehensive PCB assembly service seamlessly integrates with our fabrication capabilities, providing you with a one-stop solution for your printed circuit board needs. We manage the entire assembly process, from component sourcing and procurement to final testing and inspection, ensuring a smooth and efficient transition from pcb design to a fully assembled product.

“Their expertise in PCB assembly has been instrumental in the success of our products. Their attention to detail and commitment to quality are truly remarkable.” – A Satisfied Customer

Our assembly process utilizes state-of-the-art automated equipment for precise component placement and soldering. We handle both surface mount (SMT) and through-hole components, ensuring that your board assemblies meet the highest standards of quality and reliability. The assembly process involves several key steps, including solder paste application, component placement, reflow soldering, and inspection. We employ advanced techniques such as automated optical inspection (AOI) and X-ray inspection to ensure the quality of each pcb assembly. Our team is well-versed in the latest assembly technologies and can handle a wide range of components, from fine-pitch integrated circuit to large, complex connectors. Learn more about our pcb assembly process and how we can help you streamline your production. We also offer quick turn pcb services for projects that require a fast turnaround time.

Environmental Impact: We are committed to sustainable manufacturing practices. Our fabrication and assembly process are designed to minimize waste and reduce our environmental footprint. We comply with RoHS directives and other environmental regulations.

Customer Reviews: “The quality of their printed circuit board manufacturing is exceptional. They consistently deliver high-quality pcbs that meet our stringent requirements.” – Industry Leader. “Their pcb design expertise has been invaluable to our product development process. They provide innovative solutions to complex challenges of pcb design.” – Loyal Customer. “Their customer service is outstanding. They are responsive, knowledgeable, and always willing to go the extra mile.” – Satisfied Partner. Explore our multilayer pcb options for advanced applications.

Useful Information: Printed circuit boards are used in a vast array of electronic devices, from smartphones and computers to medical equipment and automotive systems. The complexity of modern printed circuit boards can range from simple single-sided boards to complex multi-layer pcb with high density interconnect (hdi pcbs). The choice of substrate material depends on the application and can include FR-4, polyimide, or even metal-core for improved thermal management. The design process for a pcb involves creating a schematic diagram, which is then translated into a physical layout using specialized design tools. The gerber files generated during the design process are used for printed circuit board fabrication. Printed circuit board assembly involves mounting electronic components onto the bare board using soldering techniques. Discover the benefits of our flexible pcb solutions.

Chart: Global PCB Market Segmentation by Application (2023)

| Application | Market Share (%) |

|---|---|

| Consumer Electronics | 35 |

| Automotive | 25 |

| Industrial | 20 |

| Telecommunications | 15 |

| Others | 5 |

Partnering with us means gaining access to a wealth of experience, cutting-edge technology, and an unwavering commitment to quality. We are dedicated to providing you with printed circuit board solutions that empower your innovations and propel your success in the ever-evolving landscape of electronics. Contact us today to discuss your pcb needs and discover how we can help you achieve your product development goals. Our rigid-flex pcb services offer unique solutions for demanding applications.

Product Advantages Summary:

“Your PCBs are the bedrock of our products’ success – your precision manufacturing and expert pcb assembly give us the reliability and performance we need to lead the market.”

Help Center

Query about PCB manufacturing? Please check this question and answers